From Corrosion to Confidence

How PSS Ceramic Rotors Transformed Fleet Maintenance.

Download Case StudyThe Problem

The client’s fleet was equipped with PSS Shaft Seals utilizing a 316L stainless steel rotor. After just 2 - 3 years of service, the mating face of the rotor would begin to corrode, leading to seal leakage. This recurring issue resulted in increased maintenance costs and vessel downtime, as the rotor required frequent replacement to maintain seal integrity.

The corrosion observed was primarily due to electrolysis caused by stray electrical currents present in the marine environment. While 316L stainless steel offers good general corrosion resistance, it is susceptible to accelerated degradation when exposed to stray currents. These conditions create an electrochemical reaction that breaks down the protective oxide layer on the stainless steel, especially at the mating face where the seal interfaces with the carbon stator. As a result, the rotor would corrode prematurely, compromising the effectiveness of the shaft seal and necessitating frequent replacements. To address this, it was necessary to select a rotor material with superior resistance, ensuring longer service life and improved reliability for the vessels.

The Solution

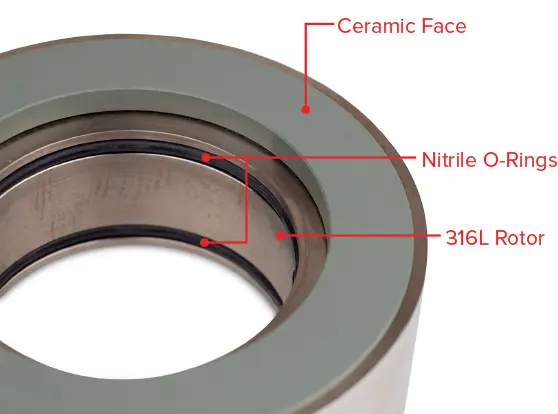

To address these challenges, PSS Seals, LLC installed a new ceramic face and rotor assembly (Part #07-300-CER) on the client’s vessels.

To overcome corrosion issues, PSS Seal employed a unique combination of materials and design modifications:

- The ceramic rotor provided superior corrosion resistance and durability compared to stainless steel.

- The lifespan of the PSS Shaft Seal was significantly extended, reducing the frequency of replacements and costly maintenance.

Added Value

What set the PSS Seal solution apart was its tailored approach to the client’s specific corrosion problem. By switching to a ceramic rotor, the client experienced:

- Extended Seal Life – Over 4 years with no issues, compared to 2 - 3 years previously.

- Enhanced Safety & Reliability – Provided a high-performance propeller shaft seal, reducing the risk of leaks and ensuring dependable operation over time.

- Cost Efficiency – Minimized the need for frequent maintenance or expensive repairs by offering a durable and reliable solution.

- Customer Satisfaction – Exceeded client expectations by addressing their unique challenge, reinforcing PSS Seal’s commitment to quality and customer-centric solutions.

Benefits to the Client

- Previous MTBF: 2 - 3 years

- New MTBF: 4+ years (and ongoing)

- ROI / Cost Savings: Reduced frequency of replacements and maintenance, leading to significant cost savings

- Other Benefits: Improved operational reliability and reduced risk of water ingress

Additional Information

Following the success of the initial installation, the client has since replaced the seals in the remaining fleet with PSS Shaft Seals using the ceramic rotor, demonstrating repeat business and satisfaction with the solution.

| Industry: | Marine |

|---|---|

| Products: | PSS Pro Shaft Seal, part #03-300-412 Ceramic Rotor, part #07-300-CER |

| Application: | Passenger vessel |

| Savings: | Reduced maintenance cost and downtime |