Flow Tanks & Space Sensitive Installs

PSS Seal's ability to customize solutions allow PSS mechanical seals to be integrated into space sensitive installations on specific pumps and flow tanks.

Compact Design

Innovative compact design allows for installation where space is extremely limited.

Water Tight

Due to the mechanical face seal created between the rotating stainless steel rotor and the stationary carbon stator there's no water leaks.

Why PSS?

Flexible Design: In addition to carrying standard sizing, a major advantage of the PSS Shaft Seal is its ability to be customized to adapt to an existing installation or design. Because of the ability to design the seal to fit most existing systems, engineers are unconstrained by seal size requirements. The time frame for custom seals is usually very low, 3 to 4 weeks.

Reliable & Durable: Due to its simple design the PSS Shaft Seal is durable and reliable, with a typical life span of 25,000 running hours. Under clean water conditions the seal can exceed 100,000+ running hours. The unique "float design" & flexibility of the PSS Shaft Seal allows for substantial axial movement of the shaft while still operating correctly.

Low maintenance & Ease of Installation: Minimal maintenance is required under normal working conditions with replacement parts readily available. Unlike other sealing systems, the seal does not wear the shaft or surrounding materials during operation which results in longer maintenance intervals.

Certifications

All PSS mechanical seals have these certifications.

ABS Certified

Bureau Veritas Certified

RINA Certified

Specifications

| Materials: | Rotor: 316L stainless steel Carbon Stator: high density, resin impregnated carbon graphite Bellow: Five ply cloth inlay with flurosilicone outer |

| Size: | Can manufacture to any size and application |

| Operating Temperature: | -25°F to +225°F (-31°C to +107°C) |

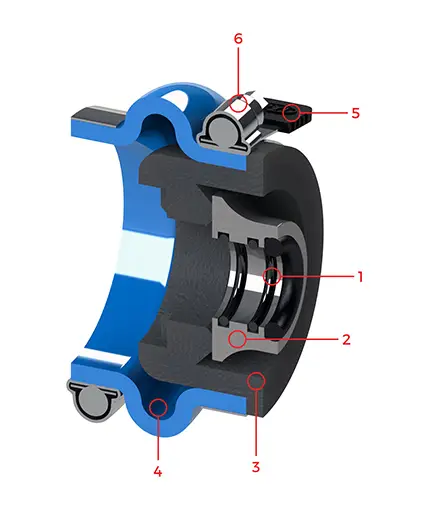

PSS Seal Components

- Nitrile o-rings

- 316L stainless steel rotor

- Carbon graphite stator

- Nitrile or reinforeced silicone bellow (depending on requirements)

- Clamp Jacket - (rubber hose clamp protectors)

- Hose clamps