Flexible Design

Customizable sizing to adapt to existing applications in addition to standard sizes.

Reliable

Simple, durable design ensures seal longevity.

Low Maintenance

Minimal maintenance required, reducing downtime.

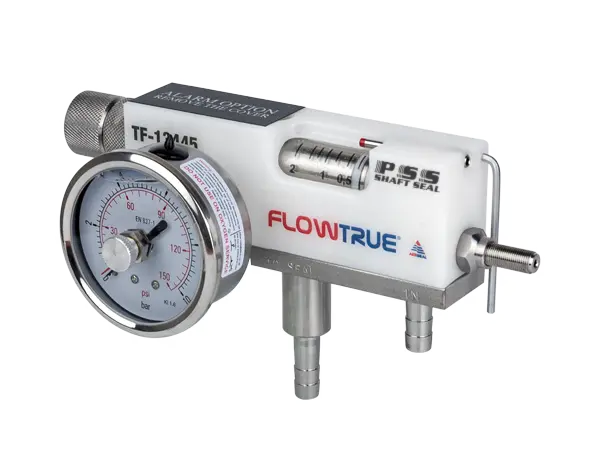

FlowTrue

Precision Water Control for Shaft Seals

Adjustable Flow Meter

Controls the amount of water flowing to the shaft seal for cooling purposes.

Cleaning Mechanism

The device can be cleaned without interrupting flow and pressure to the seal.

Unique Segmental Valves

Prevents FlowTrue from clogging.

Why Use A PSS Shaft Seal?

Flexible Design

In addition to carrying standard sizing, a major advantage of the PSS Shaft Seal is its ability to be customized to adapt to an existing installation or design. Because of the ability to design the seal to fit most existing systems, engineers are unconstrained by seal size requirements. The time frame for custom seals is usually very low, 3 to 4 weeks.

Reliable & Durable

Due to its simple design the PSS Shaft Seal is durable and reliable, with a typical life span of 25,000 running hours. Under clean water conditions the seal can exceed 100,000+ running hours. The unique "float design" & flexibility of the PSS Shaft Seal allows for substantial axial movement of the shaft while still operating correctly.

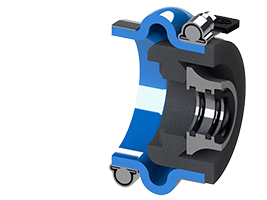

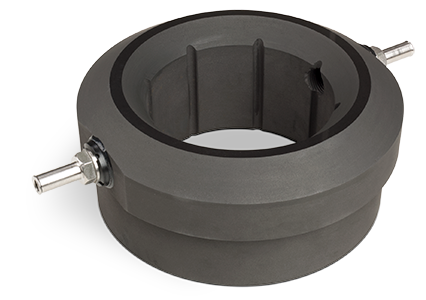

Components

The PSS Shaft Seal consists of three basic components, the stainless steel rotor, carbon stator and the bellow. As shown below is a detailed image and description of each component. Please note that the size and aesthetics of each component may vary depending on the application.

Stainless Steel Rotor

| Materials: | 316L stainless steel or Nitronic 50 |

| Size: | Varies depending on application |

| Operating Temperature: | TBD |

The PSS 316L stainless steel rotor is slid down the shaft and is secured to the shaft with set screws at 90° for maximum holding power.

Precision tolerances are maintained by computer controlled lathes. the faces have a number 9 micro finish and are perpendicular to the bore to prevent run-out as the collar rotates. The carbon graphite stator will polish the face of the rotor during the first few minutes of operation. The stainless steel rotor should not need to be replaced under normal operating conditions.

More InfoCarbon Graphite Stator

| Materials: | carbon graphite |

| Size: | Varies depending on application |

| Operating Temperature: | 500°F (+250°C) |

Carbon-graphite is a versatile seal face material used with mating rings of harder material. The PSS carbon has superior wear characteristics and broad chemical resistance.

The face of the carbon is finished to a flatness of 4 helium light bands (measured .000044" of variation over entire lapped surface). The grade of carbon used in the PSS has an operating temperature over 500°F (+260°C), and cannot melt if the seal runs dry, unlike a rubber lip seal or plastic face seal.

The high density of the carbon greatly increases the longevity and wear resistance. Over 40,000 hours (over 4.5 years of continuous operation) has been recorded on the same original component. The carbon graphite stator should not need to be replaced under normal operating conditions.

More InfoBellow

| Materials: | Nitrile or reinforced silicone |

| Size: | Varies depending on application |

| Operating Temperature: | Nitrile: -25°F to +225°F (-31°C to +107°C) Silocone: -90°F to +425°F (-70°C to +220°C) |

Nitrile: The nitrile rubber bellow has a temperature rating of -25°F to +225°F (-31°C to +107°C). Nitrile is known for its great resistance to hydrocarbons, but is subject to deterioration by ozone gas as well as corrosive agents.

Silicone: The silicone reinforced bellow is constructed of five ply aramid/silicone with a flurosilicone outer. Both ends of the bellow are sealed in order to prevent wicking. The five ply cloth inlay provides excellent strength and resistance to abrasion. The strength of the bellow is greatly increased by fitting stainless steel hoops in the convolutions of the bellow. This bellow has a continuous operating temperature range of -90°F to +425°F (-70°C to +220°C). Silicone also shows great resistance to ozone as well as corrosive agents.

These bellows provide the best combination of durability, strength and elasticity.

More Info

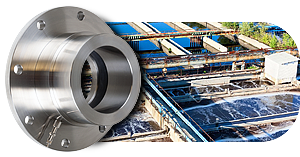

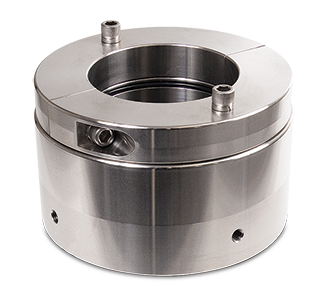

Kenosha Water Utility

The Kenosha Water Utility from Kenosha, WI had begun the retrofit of all the old stuffing box type configurations at their water production plant on "thru wall" mixer shafts for their water purification plant. They were looking for a solution to replace the leaking and worn out traditional seals with something that will last, reduce cost, reduces plant down time due to seal maintenance and eliminate leaking. PSS Seal provided pressure resistant PSS Shaft Seal as well as mounting flanges for this retrofit project.

More Info

FPI Axial Flow Propeller Pumps

FPI’s axial flow pumps are able to handle large volumes of water, ranging from 1,000 to 120,000 gallons per minute. FPI needed a seal for the impeller shaft that could handle that kind of a work load. PSS Seal was able to provide a very cost effective solution that is easy to install, reduces maintenance / shut down on their pumps and durable enough to withstand the harsh environment they are often subject to.

More InfoContact PSS Seals

Need technical support? Can't find what you're looking for?